Add Date: 2024/6/13 Views: 218

Keyword:# Small machining center, # Desktop machining center, # Small five axis machining center, # Desktop teaching machining center, # Pilot five axis linkage machining center

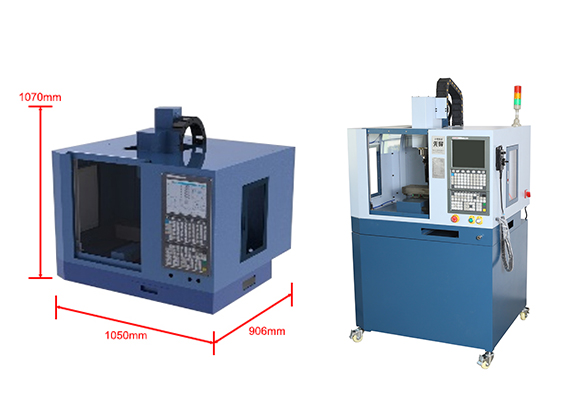

XENDOLL small five axis linkage machining center can serve as a teaching tool for schools or training institutions, helping students understand the basic principles and operating methods of CNC machining. It is particularly suitable for students majoring in mechanical, automation, industrial design, and other related fields to carry out practical operations and course projects.

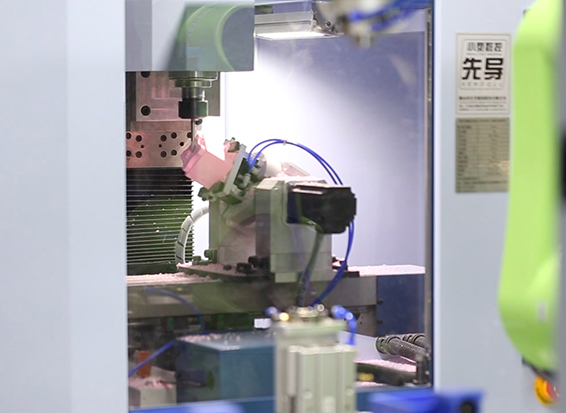

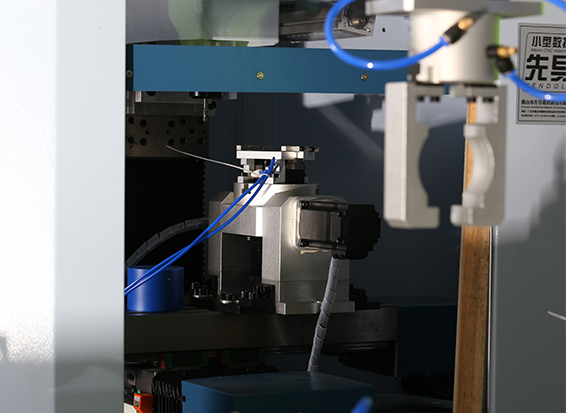

A small five axis linkage machining center is a machining equipment that can simultaneously control five degrees of freedom for linkage. These five degrees of freedom include three linear motion axes (X-axis, Y-axis, Z-axis) and two rotation axes (A-axis, C-axis). Through the linkage of these five axes, a small five axis linkage machining center can achieve high efficiency and precision machining of various complex parts.

Compared with traditional large-scale CNC machine tools, desktop machining centers have higher flexibility and portability, and can be widely used in homes, schools, laboratories and other places. It usually adopts precise control systems and high-performance cutting tools, which can achieve precise machining of various materials.

XENDOLL desktop machining center is commonly used in scientific research institutions in universities for the processing of first boards, samples, and small batch products. It can achieve various processing operations, including milling, carving, and other processes. Equipped with five axis five linkage function, capable of processing complex multi process parts. They are used in the maker innovation laboratory to process functional metal components and casings of various creative products, as well as for first board processing and metal model five axis processing.

XENDOLL desktop machining center can process various materials, such as copper parts, aluminum parts, steel parts, plastic parts, etc. They are usually equipped with servo motors, which run faster and more stable, resulting in more ideal processing effects and higher accuracy. Desktop machining centers are also suitable for the vocational education industry and are used for training in programming and processing of five axis CNC machine tools.

The small five axis linkage machining center can achieve high efficiency and precision machining of various complex shapes and surfaces through its five axis linkage. In addition, such devices usually have advanced configurations such as high-precision linear guides, excellent cast iron material casting, high-precision grinding ball screws, etc., to ensure processing quality and efficiency.

The five axis linkage machining center (also known as the five axis machining center) is suitable for processing various complex parts, and its high precision and efficiency characteristics make it widely used in many industries.

As an important tool for CNC vocational education, XENDOLL desktop machining center has educational significance in deepening the integration of industry and education, and promoting the development of vocational education. By introducing desktop machining centers, the aim is to solidify the foundation of vocational education, improve the vocational education and training system, provide students with a more authentic and efficient teaching environment, and cultivate professional talents that meet social needs.